Published 11/28/23 by Groundhog Equipment

Operating an excavator efficiently is key to a successful construction or landscaping project. One crucial aspect that operators often encounter is the choice between ISO and SAE control patterns. In this guide, we’ll walk you through the process of switching excavator controls from ISO to SAE, ensuring that you can seamlessly adapt to different operational requirements.

Understanding ISO and SAE Control Patterns: Before delving into the switch, it’s essential to grasp the fundamental differences between ISO (International Organization for Standardization) and SAE (Society of Automotive Engineers) control patterns. These patterns dictate the movement of the excavator’s boom, stick, and bucket based on the operator’s input.

ISO Controls: Widely used in North America, the SAE pattern reverses the controls, with the left joystick managing the bucket and stick, and the right joystick controlling the swing and boom.

SAE Controls: Commonly used in Europe and other parts of the world, the ISO pattern has the left joystick controlling the swing and boom, while the right joystick manages the bucket and stick.

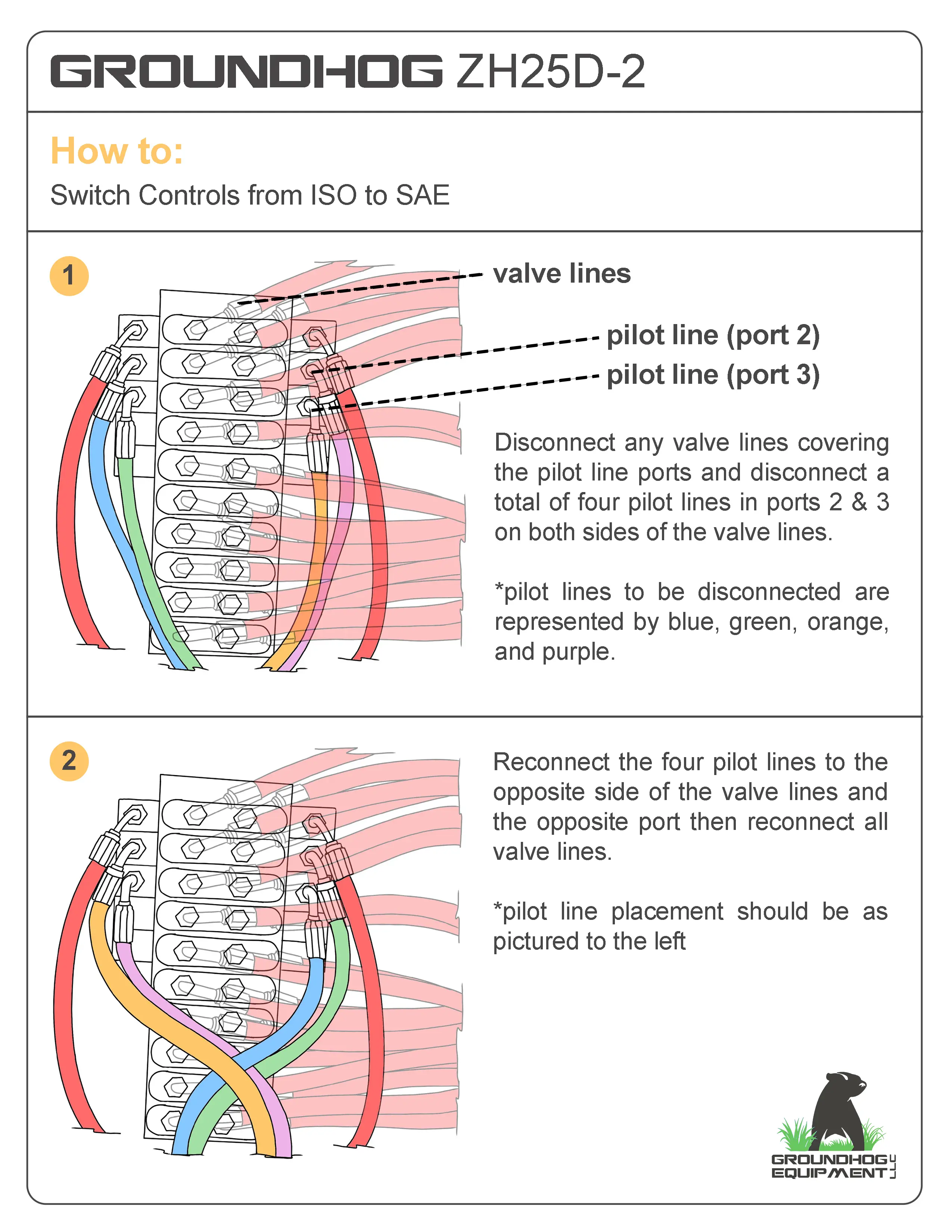

Step-by-Step Guide to Switching Excavator Controls:

Locate the Control Pattern Switch (some machines are not equipped with a switch and must be done manually):

Identify the control pattern switch on your excavator. This switch is typically located near the operator’s seat or on the control panel.

Ensure the Excavator is Turned Off:

For safety reasons, always ensure that the excavator is turned off before attempting to switch control patterns.

Adjust the Control Pattern Switch:

Depending on your excavator model, use the designated switch or lever to change the control pattern. Refer to your operator’s manual for specific instructions on your machine.

Verify the New Pattern:

After making the switch, take a moment to verify that the controls now align with the desired pattern. Engage each joystick to confirm the correct movement of the boom, stick, bucket, and swing.

Practice in a Controlled Environment:

Before tackling a project with the new control pattern, practice in a controlled environment to familiarize yourself with the adjustments. This step is particularly important for operators transitioning between ISO and SAE patterns.

Tips for a Smooth Transition:

Familiarize yourself with the specific control symbols and labels on your excavator.

Take advantage of any training resources provided by the excavator manufacturer or your employer.

Communicate with your team to ensure everyone is aware of the control pattern being used on the job site.

Mastering the art of switching excavator controls from ISO to SAE opens up a world of possibilities for operators. Whether you’re working on diverse job sites or collaborating with teams using different control patterns, this skill enhances your adaptability and efficiency. Remember, practice makes perfect, so take the time to hone your skills and confidently switch between control patterns as the need arises.